PRODUCT OVERVIEW

The self operated electronic control temperature regulating valve is composed of a straight stroke electric actuator and a single seat or sleeve regulating valve body. It is suitable for large diameter and heat transfer oil control. The valve only needs ordinary 220V power supply, and uses the heat of the regulated medium to automatically adjust and control the temperature of steam, hot water, hot oil and gas. It can also be used to prevent overheating or heat exchange. The self operated electric control temperature regulating valve has the advantages of simple structure, convenient operation, wide temperature range, fast response time and reliable sealing performance, and can be adjusted at will during operation. Therefore, self operated electronic control temperature regulating valve is widely used in hot water supply in chemical industry, petroleum, food, textile, hotels and restaurants.

PRODUCT FEATURES

1. Only single-phase AC 220V power supply and temperature sensor (temperature bag) can form a temperature control system on the use site. It can directly replace the temperature bag and self-supporting regulating valve, and there is no need to connect the temperature controller and actuator. It is the perfect combination of regulating system and self-supporting valve.

2. There is a highly integrated fdy-258t temperature control module in the actuator, which combines the temperature controller and the actuator to realize electromechanical integration and simplify the temperature control system.

3. High control precision, fast response, stable and reliable performance and long service life.

4. Wide application range, temperature control can be carried out in a wide temperature range.

5. Compact structure, easy installation, debugging and use.

MAIN TECHNICAL PARAMETERS

| Nominal diameter(mm) | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

|---|

| Circulation capacity(m3/h) | 7 | 10 | 16 | 25 | 40 | 63 | 100 | 160 | 250 | 400 | 630 |

| Rated stroke(mm) | 6 | 8 | 10 | 14 | 20 | 30 | 30 | 40 |

| Bonnet form | Standard type - 17 ~ + 230 ℃, high temperature type + 230 ~ + 450 ℃ |

| Gland type | Bolt compression type |

| Sealing packing | V-type polytetrafluoroethylene filler, impregnated polytetrafluoroethylene asbestos filler, asbestos textile filler and graphite filler |

| Spool form | Single seat and sleeve valve core |

| Flow characteristics | Straightness |

| Adjustment accuracy (℃) | ± 1 ~ ± 5 |

| Use media | Steam, water, oil, gas |

| Allowable leakage | Hard seal | 10 -4 X Valve rated capacity |

| Soft seal | "0" |

| Temperature bag and capillary material | H62、1Cr18Ni9Ti |

| Capillary length | 3meters、5meters、10meters |

| Temperature control range | 0~250℃ |

| Setpoint deviation | ±2℃ |

| Actuator model | 3810l series, PSL series |

| Main technical parameters | Power supply voltage: 220V / 50Hz, input signal: 4-20mA or 1-5V · DC, output signal: 4-20mA · DC |

| Protection grade: equivalent to IP55, flameproof sign: Exd Ⅱ BT4, manual operation function: handle |

| Ambient temperature: - 25 ~ + 70 ℃, ambient humidity: ≤ 95% |

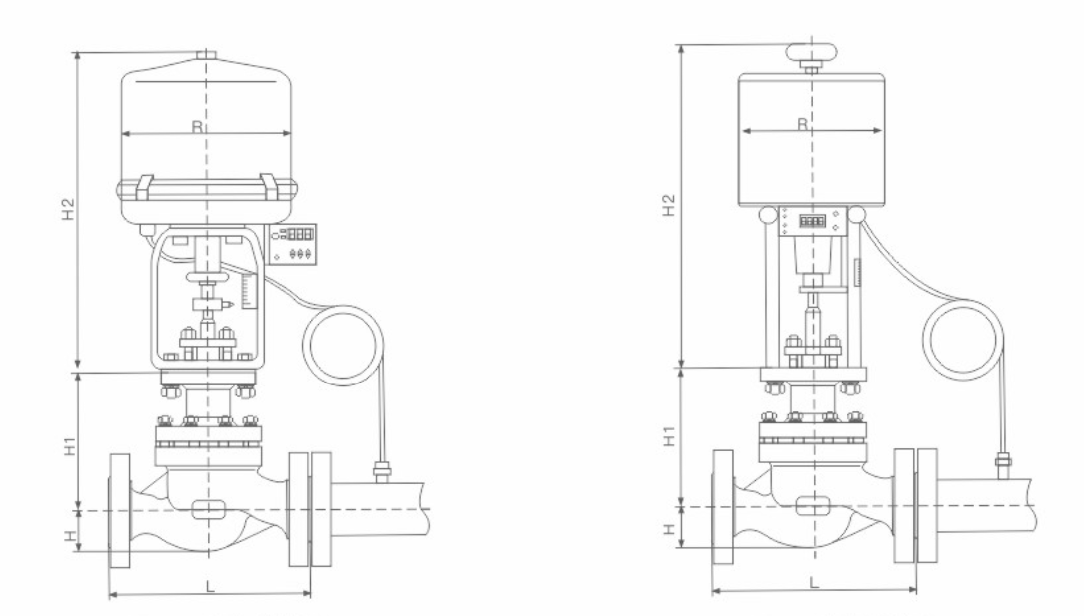

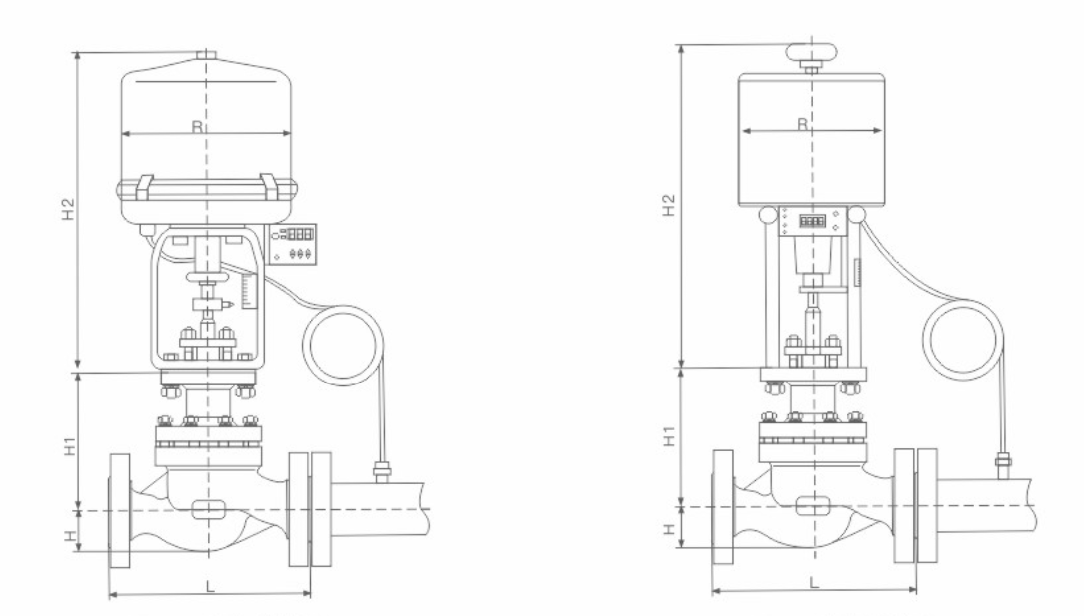

MAIN CONNECTION DIMENSIONS

| Nominal diameter(DN) | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

|---|

| L | PN16/25 | 181 | 184 | 200 | 222 | 254 | 276 | 298 | 352 | 410 | 451 | 600 |

| PN40 | 194 | 197 | 200 | 235 | 267 | 292 | 317 | 368 | 425 | 473 | 610 |

| PN64 | 206 | 200 | 210 | 251 | 286 | 311 | 337 | 394 | 440 | 508 | 650 |

| H | PN16/25 | 52.5 | 57.5 | 75 | 75 | 85.5 | 92.5 | 100 | 110 | 142.5 | 158 | 170 |

| PN40 | 52.5 | 57.5 | 75 | 75 | 82.5 | 92.5 | 100 | 117.5 | 150 | 167.5 | 187.5 |

| PN64 | 65 | 40 | 85 | 85 | 90 | 102.5 | 107.5 | 125 | 172.5 | 195 | 207.5 |

| H1 | 132 | 132 | 158 | 170 | 179 | 214 | 221 | 234 | 270 | 294 | 331 |

| H2 | 3810L | 373 | 373 | 495 | 495 | 495 | 700 | 700 | 700 | 725 | 725 | 725 |

| PSL | 465 | 465 | 465 | 465 | 465 | 560 | 560 | 560 | 560 | 560 | 788 |

| D | 3810L | 225 | 225 | 225 | 225 | 225 | 257 | 257 | 257 | 310 | 310 | 310 |

| PSL | 177 | 177 | 177 | 177 | 177 | 182 | 182 | 182 | 182 | 182 | 218 |