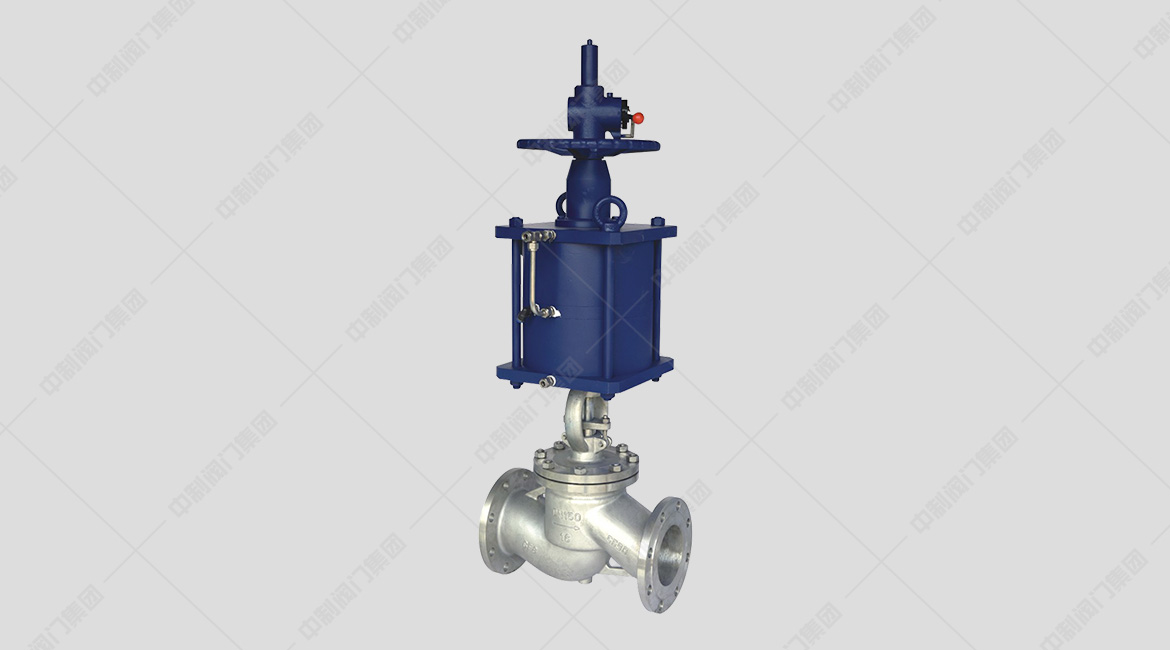

PRODUCT OVERVIEW

Pneumatic stop valve has a position that can not be ignored in modern industrial transmission pipelines. It is assembled by piston pneumatic actuator and stop valve. The medium flow channel is designed as a forced sealing valve with low inlet and high outlet. Stellite alloy seal is adopted, which has good sealing performance and wear resistance. It is especially suitable for pipelines under various working conditions in petroleum, chemical industry, pharmaceutical, chemical fertilizer, electric power industry and so on. Take the compressed air as the power and receive the industrial signal command to complete the opening and closing of the valve.

PRODUCT FEATURES

1. It can be installed at any position of the pipeline. The flow channel design with low medium inlet and high medium outlet can increase the tightness and sufficient strength of the valve.

2. The sealing surface of valve disc and valve seat is made of iron-based alloy surfacing or Stellite cobalt based cemented carbide surfacing. It has good wear resistance, high temperature resistance, corrosion resistance, scratch resistance and long service life.

3. The valve rod has good corrosion resistance and scratch resistance after quenching and tempering and surface nitriding treatment.

4. Various piping flange standards and flange sealing surface types can be adopted to meet various engineering needs and user requirements.

5. The valve body has a complete variety of materials. The packing and gasket can be reasonably selected according to the actual working conditions or user requirements, and can be applicable to various pressure, temperature and medium working conditions.

6. The inverted seal is made of threaded connection seal seat or austenitic stainless steel overlaying on the body. The seal is reliable. The replacement of filler can be carried out without shutdown, which is convenient and fast and does not affect the operation of the system.

MAIN TECHNICAL PARAMETERS

| Nominal diameter | DN50~800mm |

|---|

| Connection mode | Flange |

| Cylinder form | Double acting, single acting (spring return) |

| control mode | Switch type, regulating type |

| Nominal pressure | 16、25、40bar(If higher pressure is required, please indicate when ordering) |

| Air source pressure | Double action:4~8bar |

| Medium temperature | W3:-30~425℃ W4:-40~425 |

| ambient temperature | Standard type: - 20 ~ 80 ℃ |

| body material | Carbon steel (c), stainless steel (P4, P6) |

| Sealing material | Metal hard seal (H), cemented carbide (y) |

MATERIAL OF MAIN PARTS

| Serial number | Part name | Texture of material |

|---|

| C | P4 | P6 |

|---|

| 1 | valve body | WCB | ZG1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 2 | Shim | Flexible graphite + stainless steel | PTFE | PTFE |

| 3 | Bolt | 35 | 304 | 304 |

| 4 | Spiral valve | WCB + surfacing 304 or stelite, PTFE | ZG1Cr18Ni9Ti PTFE | ZG1Cr18Ni12Mo2Ti PTFE |

| 5 | Split ring | 1Cr18Ni9Ti | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 6 | Disc cover | 1Cr18Ni9Ti | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 7 | Valve stem | 2Cr13 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 8 | Nut | 35 | 304 | 304 |

| 9 | Eyebolt | 35 | 304 | 304 |

| 10 | Valve cover | WCB | ZG1Cr18Ni9Ti | ZG1Cr18Ni12Mo2Ti |

| 11 | Bolt | 35 | 304 | 304 |

| 12 | Shim | 35 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 13 | Filler | Flexible graphite | PTFE | PTFE |

| 14 | Packing pressing plate | WCB | ZG1Cr18Ni9Ti | ZG1Cr18Ni12Mo2Ti |

| 15 | Nut | 35 | 304 | 304 |

MAIN OVERALL DIMENSIONS

| Nominal pressurePN(MPa) | Nominal diameterDN(mm) |

Standard value |

Reference value |

|

L |

D |

D1 |

n2 |

D6 |

b |

f |

f1 |

Z-φd |

L1 |

H |

|

1.6 |

50 |

230 |

160 |

125 |

100 | / |

16 |

3 | / |

4-φ18 |

185 |

645 |

|

65 |

290 |

180 |

145 |

120 | / |

18 |

3 | / |

4-φ18 |

232 |

690 |

|

80 |

310 |

195 |

160 |

135 | / |

20 |

3 | / |

8-φ18 |

232 |

715 |

|

100 |

350 |

215 |

180 |

155 | / |

20 |

3 | / |

8-φ18 |

232 |

770 |

|

125 |

400 |

254 |

210 |

185 | / |

22 |

3 | / |

8-φ18 |

283 |

780 |

|

150 |

480 |

280 |

240 |

210 | / |

24 |

3 | / |

8-φ23 |

283 |

810 |

|

200 |

600 |

335 |

295 |

265 | / |

26 |

3 | / |

12-φ23 |

283 |

967 |

|

250 |

622 |

405 |

355 |

320 | / |

30 |

3 | / |

12-φ25 |

283 |

1143 |

|

300 |

698 |

460 |

410 |

375 | / |

30 |

4 | / |

12-φ25 |

283 |

1292 |

|

2.5 |

50 |

230 |

160 |

125 |

100 | / |

20 |

3 | / |

4-φ18 |

185 |

645 |

|

65 |

290 |

180 |

145 |

120 | / |

22 |

3 | / |

8-φ18 |

232 |

690 |

|

80 |

310 |

195 |

160 |

135 | / |

22 |

3 | / |

8-φ18 |

232 |

715 |

|

100 |

350 |

230 |

190 |

160 | / |

24 |

3 | / |

8-φ23 |

232 |

770 |

|

125 |

400 |

270 |

220 |

188 | / |

28 |

3 | / |

8-φ25 |

283 |

780 |

|

150 |

480 |

300 |

250 |

218 | / |

30 |

3 | / |

8-φ25 |

283 |

810 |

|

200 |

600 |

360 |

310 |

278 | / |

34 |

3 | / |

12-φ25 |

283 |

967 |

|

250 |

622 |

425 |

370 |

332 | / |

36 |

3 | / |

12-φ30 |

283 |

1143 |

|

300 |

698 |

485 |

430 |

390 | / |

40 |

4 | / |

16-φ30 |

283 |

1292 |

|

4.0 |

50 |

230 |

160 |

125 |

100 |

88 |

20 |

3 |

4 |

4-φ18 |

185 |

645 |

|

65 |

290 |

180 |

145 |

120 |

110 |

22 |

3 |

4 |

8-φ18 |

232 |

690 |

|

80 |

310 |

195 |

160 |

135 |

121 |

22 |

3 |

4 |

8-φ18 |

232 |

715 |

|

100 |

350 |

230 |

190 |

160 |

150 |

24 |

3 |

4.5 |

8-φ23 |

232 |

770 |

|

125 |

400 |

270 |

220 |

188 |

176 |

28 |

3 |

4.5 |

8-φ25 |

283 |

782 |

|

150 |

480 |

300 |

250 |

218 |

204 |

30 |

3 |

4.5 |

8-φ25 |

283 |

875 |

|

200 |

600 |

375 |

320 |

282 |

260 |

38 |

3 |

4.5 |

12-φ30 |

283 |

1160 |