PRODUCT OVERVIEW

Hydraulic control slow-closing ball valves for hydropower stations are mainly used in large and medium-sized hydropower stations. It is installed in front of the turbine and used as the inlet valve of the turbine. The upstream is connected with the penstock, and the downstream is connected with the volute inlet pipe. On the one hand, when the water turbine or generator needs to be overhauled; the valve can be used to cut off the water flow in the pipeline for safe overhaul. On the other hand, when the turbine or generator is abnormal, the water flow can be cut off quickly and effectively to prevent accidents.

Hydraulic control slow-closing ball valve of hydropower station can be used in the medium containing mud and water. This valve can only be used as a shut-off valve and cannot be used to adjust flow.

PRODUCT FEATURES

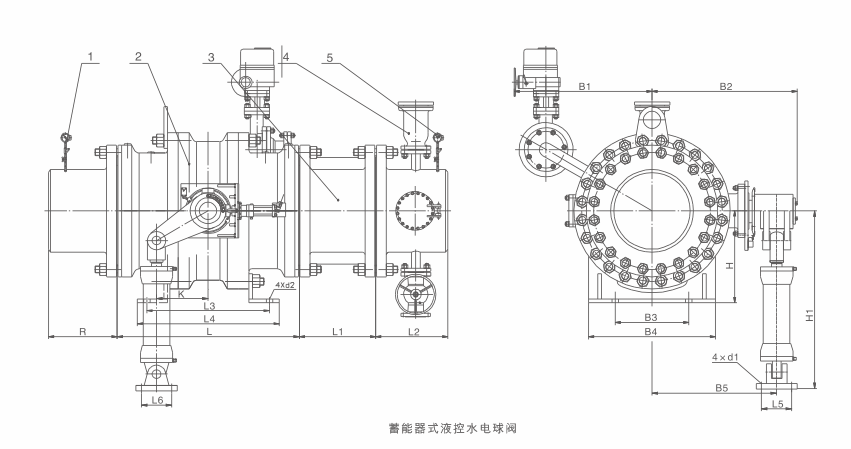

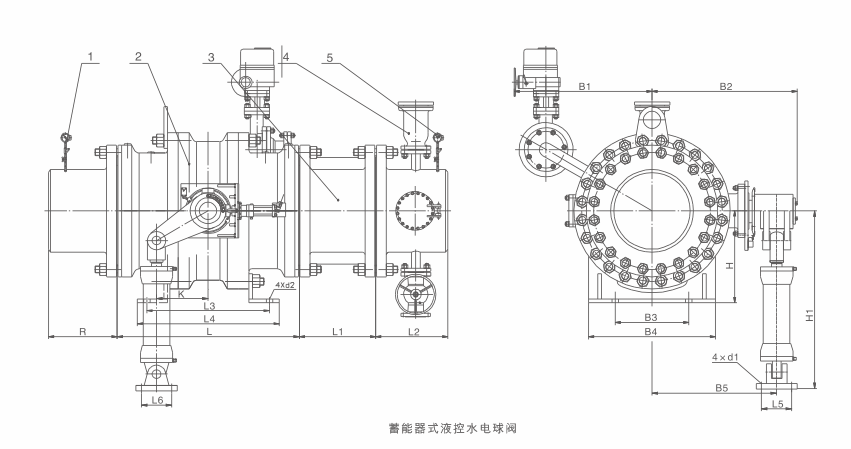

1. Hydraulic control slow closing ball valve of hydropower station is mainly composed of mechanical valve system, mechanical transmission system, hydraulic control system, electrical automatic control system, bypass system, upstream takeover, downstream telescopic takeover, discharge system, etc.

2. Mechanical valve system: mainly includes valve body, sphere, valve stem, and movable valve seat. This part is the core of the entire valve, which mainly cuts off the water flow in the pipeline.

3. Mechanical transmission system: mainly includes box, gear, rack, cylinder, stroke indicator. The mechanical transmission part is mainly to drive the valve to open and close and send the position signal from the stroke close.

4. Electrical automatic control system: mainly includes electrical control box, low-voltage electrical accessories, intelligent controller PLC, switching power supply, etc. Its function is to realize the opening and closing action of the valve through the intelligent control of PLC and the central control system with various logics.

5. Bypass system: including (hydraulic) control valves, manual valves, steel pipes, elbows, etc. The function of this part is to balance the upstream and downstream pressure difference before the valve is opened and closed to avoid water hammer when opening and closing the valve under the full pressure difference. And effectively reduce the operating torque of the valve. Among them, the hydraulic valve is installed downstream of the bypass pipeline, and its function is to cut or connect the bypass pipeline through hydraulic operation; the manual valve is installed before the hydraulic valve upstream of the bypass pipeline, and its function is when the (hydraulic) control valve appears In case of failure, cut off the bypass line to repair the (hydraulic) control valve.

6. Upstream connecting pipe: including connecting pipe and flange, upstream measuring pressure gauge, etc., used to connect the valve with the upstream penstock.

7. Downstream telescopic connection: including connection pipes and flanges, downstream measuring pressure gauges, etc., used to connect the valve to the downstream volute. The connection pipe and the volute are connected by flanges. Its function is to facilitate the installation of pipelines and valves. When the main valve seat is sealed, it is convenient to remove the pipe and flange and replace the sealing seat. On the other hand, it can appropriately adapt to the axial expansion and contraction of the pipeline due to changes in temperature and pressure.

8. Drainage system: including manual drain valve, manual drain valve and automatic exhaust valve. Among them, the manual drain valve is installed at the bottom end of the valve body (and also at the bottom of the entire pipeline). It is used to drain off the sediment and other dirt accumulated in the cavity of the valve body when the valve is repaired and maintained; the manual drain valve is installed at the bottom of the pipe. The bottom end, when the valve or generator is being repaired, drains the residual water flow in the pipeline to facilitate downstream inspection and repair work; the automatic exhaust valve is installed at the top of the connection pipe, and its function is to open the main valve and spray needle ( Before the guide vane is opened, the air in the pipeline is automatically discharged to avoid the serious "cavitation" phenomenon caused by the air entering the turbine blade with the water flow.

MAIN TECHNICAL PARAMETERS

| Structure length | GB/T12221 |

| Piping flange | Steel flange | GB/T9112~9131 |

| Accumulator standard | GB/T2352 |

| Test and inspection | GB/T 14478、GB/T 13927、DL/T 1068 |

| Quality assurance | ISO 9001 |

| Nominal diameter DN (mm ) | 500~3000 |

| Nominal pressure PN (MPa ) |

| 1.6~42 |

Test pressure Ps

(MPa) | Seal | 1.1xPN |

| Strength | 1.5xPN |

| Working pressure (MPa) | 0.8xPN |

| Medium temperature(℃) | ≤80 |

| Hydraulic oil | N32#-46# |

| Applicable media | Non corrosive fluids such as water, seawater, sediment water and oil products |

MATERIAL OF MAIN PARTS

| Part name | Materials |

| Body | Carbon steel |

| Paddles | Carbon steel |

| Valve shaft | Stainless steel, carbon steel |

| Body sealing surface | Copper alloy, stainless steel, STL |

| Ball plate sealing ring | High quality nitrile rubber, stainless steel |

| Sliding bearing | Copper alloy, composite bearing |

| Packing | V-ring, flexible graphite |

| Wallboard | Carbon steel |

MAIN OVERALL CONNECTION DIMENSIONS(PN1.0MPa)

| Nominal diameter(mm) | L | R | L1 | L2 | L3 | L4 | L5 | L6 | K | H | H1 | B1 | B2 | B3 | B4 | B5 | d1 | d2 |

| 500 | 1054 | 600 | 500 | 600 | 700 | 830 | 100 | 120 | 200 | 600 | 815 | 930 | 640 | 400 | 500 | 450 | 20 | 30 |

| 600 | 1232 | 600 | 500 | 600 | 750 | 880 | 100 | 120 | 200 | 650 | 815 | 1010 | 710 | 450 | 550 | 500 | 20 | 30 |

| 700 | 1397 | 600 | 600 | 600 | 850 | 980 | 120 | 150 | 250 | 700 | 905 | 1030 | 770 | 570 | 700 | 640 | 20 | 36 |

| 800 | 1651 | 650 | 600 | 650 | 1050 | 1200 | 120 | 150 | 25 | 750 | 905 | 1110 | 820 | 650 | 780 | 715 | 20 | 36 |

| 900 | 1880 | 700 | 700 | 700 | 1250 | 1400 | 160 | 200 | 300 | 800 | 1000 | 1170 | 880 | 700 | 860 | 795 | 20 | 36 |

| 1000 | 1820 | 700 | 700 | 700 | 1250 | 1400 | 160 | 240 | 350 | 850 | 1000 | 1230 | 930 | 740 | 900 | 825 | 20 | 36 |

| 1200 | 2060 | 800 | 800 | 800 | 1350 | 1600 | 200 | 240 | 400 | 950 | 1285 | 1350 | 1030 | 790 | 950 | 865 | 24 | 42 |

| 1400 | 2300 | 800 | 800 | 1250 | 1550 | 1820 | 200 | 320 | 400 | 1050 | 1285 | 1490 | 1145 | 840 | 1000 | 905 | 24 | 42 |

| 1600 | 2500 | 850 | 900 | 1250 | 1750 | 2050 | 240 | 320 | 500 | 1150 | 1410 | 1620 | 1260 | 1100 | 1300 | 1160 | 24 | 42 |

| 1800 | 2800 | 850 | 900 | 1250 | 2000 | 2350 | 240 | 400 | 5000 | 1250 | 1545 | 1750 | 1370 | 1370 | 1570 | 1260 | 24 | 42 |

| 2000 | 3000 | 900 | 950 | 1250 | 2200 | 2550 | 320 | 40 | 550 | 13540 | 1645 | 1860 | 1470 | 1400 | 1650 | 1360 | 27 | 42 |

| 2200 | 3300 | 900 | 950 | 1300 | 2500 | 2850 | 320 | 480 | 550 | 1450 | 1765 | 1970 | 1590 | 1600 | 1880 | 1480 | 27 | 42 |

| 240 | 3500 | 950 | 1000 | 1300 | 2700 | 3050 | 400 | 480 | 606 | 1550 | 1885 | 2090 | 1710 | 1740 | 2020

| 1605 | 36 | 48 |

| 2600 | 3750 | 950 | 1000 | 1300 | 2900 | 3250 | 400 | 480 | 606 | 1650 | 2015 | 2250 | 1830 | 1850 | 2200 | 1725 | 36 | 48 |

| 2800 | 3960 | 1000 | 1050 | 1300 | 3100 | 3500 | 400 | 480 | 660 | 1750 | 2115 | 2380 | 1930 | 2000 | 2400 | 1825 | 36 | 48 |

| 3000 | 4260 | 1000 | 1050 | 1300 | 3350 | 3750 | 400 | 480 | 650 | 1850 | 2245 | 2510 | 2035 | 2160 | 2560 | 1935 | 36 | 48 |